Fix bugs, one tiny resistor at a time

Share

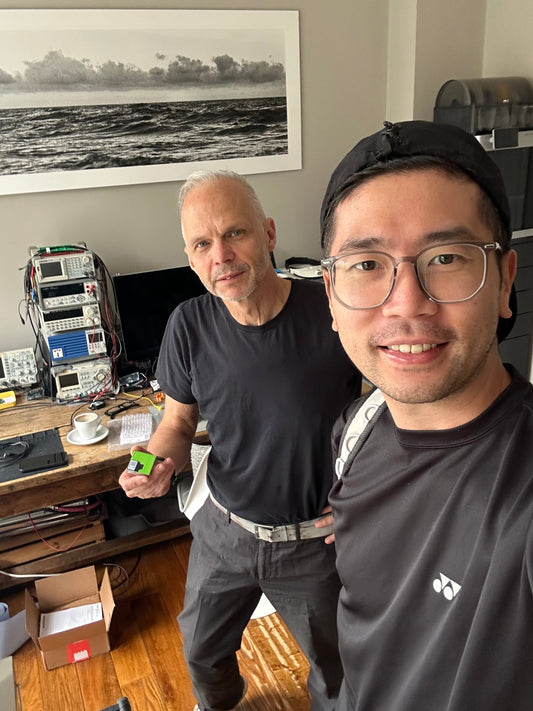

Building hardware isn’t glamorous.. it’s messy, fiddly, and sometimes involves staring at a circuit board through a magnifying glass. But it’s also one of the most rewarding parts of bringing Aira to life.

This week, we hit one of those classic hardware startup moments: the prototype bug hunt.

The problem

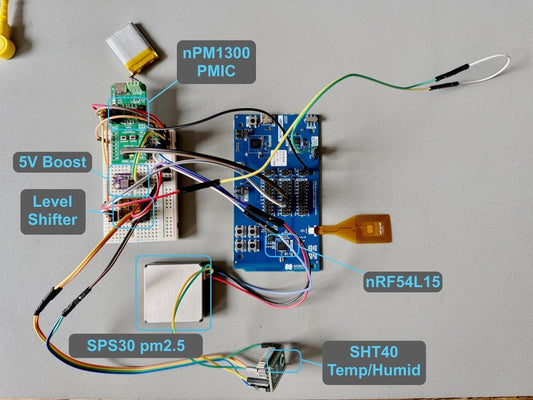

During testing, we noticed the battery charging was not as expected. At first, we thought we blew up the PCB with a Macbook charger, but after some debugging, we traced it down to the hardware itself, specifically, a couple of resistors on the PCB that weren’t behaving the way they should.

The fix

That meant getting out the soldering iron, tweezers, and a lot of patience. These aren’t the chunky resistors you might remember from school science kits, they’re tiny surface-mount components (about the size of a grain of sand). Reworking them means steady hands and plenty of coffee or the lack of.

Frankie carefully desoldered the faulty parts and resoldered new ones into place. Once they were back on the board, we powered up the device and… success! Clean signals, stable performance, and a reminder that every little detail matters when building hardware.

Why it matters

This kind of bug-fixing is normal for prototypes. Every round of testing uncovers something new to improve, and that’s exactly the point, we want to iron out these quirks now so your future device is reliable, accurate, and ready for everyday use.

The bigger picture

Fixing tiny resistors may sound small, but it’s part of the bigger story of building Aira: making the invisible visible. Every solder joint, every line of code, every late-night tweak brings us one step closer to a device that helps you understand the air you breathe.